The Vespa VNB came (to me) with an aftermarket Chinese carburetor and pod filter. It also came with a cable already attached.

I am generally wary of Chinese parts (I'll show you why in a bit) due to inferior materials and known QA problems. However, I don't want to be a hater and I am willing to at least this one a go. The original carb is still in the

treasure chest that came along with the bike, so I can always go rebuild it.

This carburetor has a slide rather than a butterfly valve as many other carbs do. When then throttle is turned, the cable pulls the slide up and the spring returns it.

At the bottom of the slide is the needle which allows fuel to flow through the main jet when pulled by the throttle. As you can see through the little keyhole in the middle of the slide, the cable stop is tucked into a little slot and then wedged in with a plastic cap.

The other end of the cable is open ended (there is no stop on it).

The original Vespa carburetor had the open end at the carb not the handle. The end of the cable loops through the little hook and is fastened back on itself.

Here's a shot of the throttle handle inside the headset. It requires a cable end like the one below to fit into the circular hole.

So the problem here is that the cable for the new carb has no stop on the handlebar end and the old cable has no stop at the carb end. I need stops at both ends for this to work and this is where I hit a wall. How do you add a stop to the end of a cable? I didn't think a crimp on stop would be strong enough for a hard-pulled throttle cable.

I found one of these screw down stops in a box of small parts and tried it out in the throttle handle. It fit through the hole but it was aluminum and had stripped out. I decided I would try this option out and went looking for some options.

I found a variety pack of them at an auto store, but even the smallest one was slightly too big for the hole on the throttle handle. The stop on the far left is the stripped out aluminum one. The brass one next to it and the one on the far right are the same size.

I used a file and some vice grips to file the outside of the stop down. I made several runs out to the scooter to test the fit. I would have just sat out there but it's Texas and it's cooler inside.

The hole for the cable was too small so I used a 3/32" bit to drill out the hole. I used the vice grips to stabilize the whole operation. My next shop is going to have a table vice.

Here is an up close comparison of the modified stop.

I think this will do the job sufficiently. Now the trick is getting it installed in the tiny space inside the headset. It will definitely work but there is some tedious fiddlefucking that will need to happen first.

On Chinese parts,

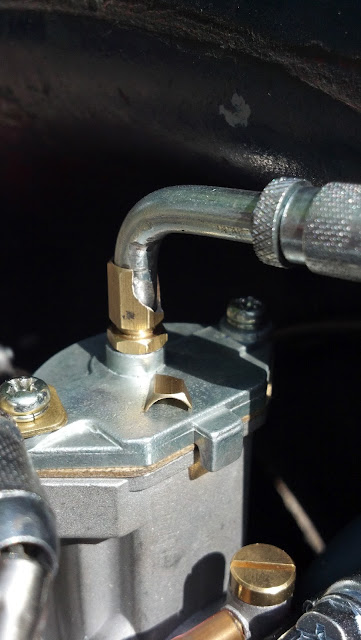

This probably should have been part of the last post about putting in new cable housing but here it is. When I was pulling the slack out of the new throttle cable housing, the tension against this brass fitting on top of the carburetor caused it to break. This should not have happened. It calls into question all of the materials on the whole assembly. I will see if I can find a sturdier replacement as this will most likely fail in the future (although this is a fairly stable connection point) but it's tempting to throw the whole thing out and reinstall the original Del Lorto carburetor. I am not trying to indict Chinese products on the whole but when your safety at speed depends on the stability of the materials your bike is made of, this sort of failure can be disastrous.